Analysis Method Ensures Better Polymer Quality

By Susan V. Greene, Senior Research Chemist, Ethyl Petroleum Additives Inc.

Researchers at Ethyl Petroleum Additives Inc. (Richmond, VA) have begun using a new analysis method to verify polymer production quality. The new method, called size-exclusion chromatography cubed (SEC³), employs technology from Viscotek Corp. (Houston; 281-445-5966). SEC³ determines the molecular weight and intrinsic viscosity of polymers more accurately than previous methods. With it, the research team identified and analyzed hidden micro-crystals in the polymers, and designed process changes to improve the quality of Ethyl's products.

Polymer Analysis Challenge

New Solution: SEC³

Results

Applications

About Ethyl Petroleum

Polymer Analysis Challenge (Back to Top)

Molecular weight distribution is a critical quality-control factor in the petroleum additive production process. Intrinsic viscosity is another polymer characteristic important in both processing and product performance.

Intrinsic viscosity is directly linked to molecular weight distribution.

Ethyl chemists formerly used conventional calibration to estimate the molecular weight of a polymer from its molecular weight distribution. Conventional calibration provides a relative measure of molecular weight by comparing the hydrodynamic volume of a sample against a standard curve.

To provide an accurate measurement, the structure of the standard set needs to be similar to that of the sample. Frequently, it is difficult to obtain appropriate standards for polymers that need to be measured. In some cases, Ethyl chemists had to prepare polymer standards to improve the conventional calibration accuracy, a time-consuming, labor-intensive process. Because some standards are extremely difficult to create, all of the polymers could not be accurately measured.

New Solution: SEC³ (Back to Top)

Ethyl chemists needed a polymer analysis method that would be faster and more accurate. The method also needed to provide a more thorough understanding of polymer architecture. Ethyl chose the SEC³ method.

SEC³ uses three detectors to provide a 3-D picture of the molecular structure. The first dimension is provided by a chromatographic process, which separates polymer molecules according to molecular size. The second is defined by the light-scattering detector response, which yields the sample's molecular weight. The third dimension is measured by the viscometer detector, which gives a response inversely proportional to the sample's molecular density.

To set up the SEC³, Ethyl chemists used a Viscotek model T60A instrument, which consists of a viscometer and a light scattering detector purchased from Viscotek Corp. This was combined with an existing differential refractive index detector, size-exclusion chromatograph pump, and autosampler system. The Viscotek viscometer-light scattering system has four-channel data acquisition capabilities. It includes TriSEC software, a sophisticated Windows-based data-processing and graphics package that is designed to analyze SEC³ data.

Results (Back to Top)

The SEC³ method has greatly improved the accuracy of molecular weight analysis at Ethyl. Rather than simply conducting a relative measurement with the differential refractive index detector, researchers can now use the new system's light scattering detector to measure the molecular weight. This approach provides more accurate molecular weight measurements than previous methods could provide. As an added bonus, the measurements are independent of the molecular structure.

The use of a light scattering detector also eliminates the need to run a calibration curve. Only a single standard of known molecular weight is required to calibrate the chromatographic system.

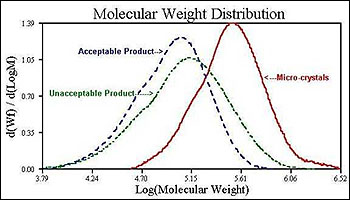

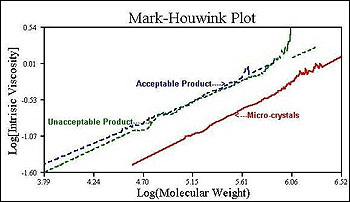

Quantitative calculation using all three chromatograms yields the molecular weight distribution, the molecular size distribution, and the intrinsic viscosity (IV) distribution. The relationship between two of these parameters is shown in a Mark-Houwink plot, which is a log-log plot of IV against molecular weight for a given sample.

The relationship between intrinsic viscosity and molecular weight is shown in this Mark-Houwink plot.

Such a plot can clearly indicate differences in branching even for samples with the same molecular weight. Because the structure is more compact, branched molecules have much lower IV values than linear molecules of the same molecular weight. If an appropriate reference branch sample is available, it would also be possible to calculate the number of branches and branching frequency for a given branched polymer sample.

Applications (Back to Top)

One of the first opportunities for Ethyl chemists to use this new technology came when micro-crystals appeared during a production process. The SEC³ clearly established that the molecular weight distribution curve had shifted toward higher molecular weight in the sample containing micro-crystals. The branching information extracted from the Mark-Houwink plot provided further insight into the architecture of the micro-crystals.

Because the researchers used the SEC³ method, they knew the molecular weight distribution and the molecular architecture. From these data, they realized that they needed to examine the production records in the plant to identify the crucial production step. The investigation highlighted one particular process parameter that was critical for the production of micro-crystals. Today, this parameter is monitored closely. Products are now created with a consistently higher quality than was previously possible.

About Ethyl Petroleum (Back to Top)

Ethyl is a major developer, manufacturer, blender, and marketer of additive products for the petroleum industry. Ethyl formulates additive packages and components which help meet or exceed a wide range of industry and government fuel and lubricant performance standards. Ethyl additives help to reduce exhaust emissions, improve fuel economy, and extend fluid and equipment life while reducing fluid consumption.

Lubricant additives are used in passenger car and heavy-duty diesel engine oils, railroad engine oils, automatic transmission fluids, gear oils, industrial lubricants, and hydraulic fluids. Fuel additives are used in gasoline, diesel fuels, aviation fuels, and heating oils.

Ethyl employs approximately 1,500 workers around the world, many of whom work at Ethyl's research facility in Richmond, VA.

For more information, call Viscotek Corp. at 281-445-5966 or fax 281-931-4336.

Written by Susan V. Greene

Susan V. Greene is a Senior Research Chemist at Ethyl Petroleum Additives Inc. (Richmond, VA).